| Plastic Part Manufacturing Process Comparison | 3D Printing / Additive Mfg | Injection Molding |

|---|---|---|

| Up front mold cost | None | Expensive – $5K and up, easily in the $10,000 plus range |

| Mold lead time | None | Usually at least 4 weeks |

| Setup cost | Low to Free, | See Mold cost |

| Ease/speed of design changes and iterations | Easy/Fast | Requires mold modification/ Slow |

| Part Cost | Low, but a little higher than IM | Low, if in thousands of pieces |

| Minimum order | As low as one, | 100’s -1,000’s (after paying for mold) |

| Materials | Most thermoplastics and some thermoset plastics | Most thermoplastics |

| Part strength | Anisotropic | Isotropic |

| Part geometry | Almost unlimited, allows complex geometries that can reduce part count and assembly time and are impossible for IM | Limited to mold limitations, No overhangs, not voids, etc. |

| Surface finish | Usually textured, not shiny smooth | Smooth to rough |

Additional Notes About Plastic Part Manufacturing

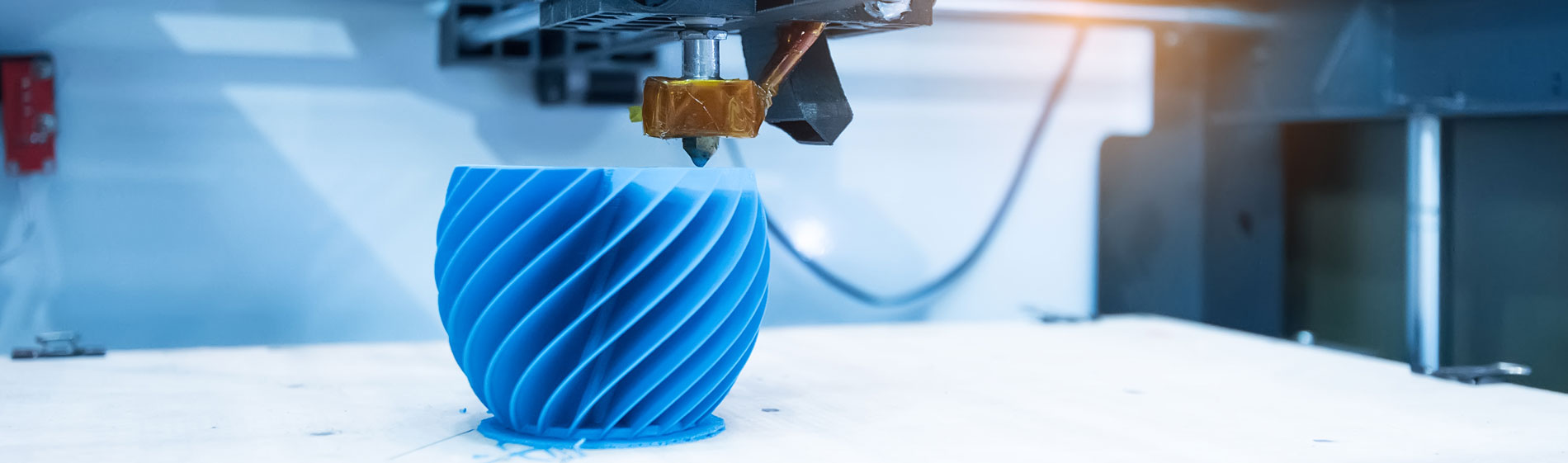

When it comes to plastic part manufacturing, each process has pros and cons. Likewise, each process has different design criteria in order to optimize the end results. Just one example, plastic parts manufactured via Injection Molded (IM) parts generally have draft angles on all sides to aid in the ejection of the parts from the mold. Those angles are not needed for 3D printing/Additive Manufacturing (AM). Likewise, IM parts are generally hollow on one side with ribs and gussets added for strength, whereas AM parts can be solid on all sides, but the interior is usually partially hollow with an infill pattern for strength. The infill density depends on the specs of the part.

Here at Paxton Engineering, our product engineers stand ready to discuss all your plastic part manufacturing needs and aid you both in determining the best solution for your needs as well as assist you in optimizing your designs for your chosen process.

Note 2

Here at Paxton Engineering Inc., we can also assist you with your non-plastic manufacturing needs as well, not to mention your overall design engineering needs. Contact us today to learn more.